Telehandler

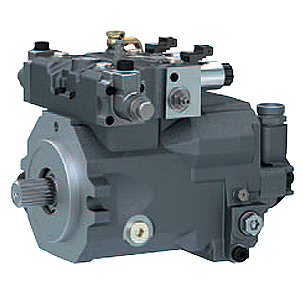

1x HPV 55-02 CA Displacement size from 55 to 280 ccvariable pumps for closed circuit operation

Learn More

1x HPV 55-02 CA Displacement size from 55 to 280 ccvariable pumps for closed circuit operation

Learn More

1x HMV 165-02 EH1P-CA PTO Displacement size from 55 to 280 ccvariable displacement motors for closed and open loops

Learn More

1x HMV 165-02 EH1P-CA PTO Displacement size from 55 to 280 ccvariable displacement motors for closed and open loops

Learn More

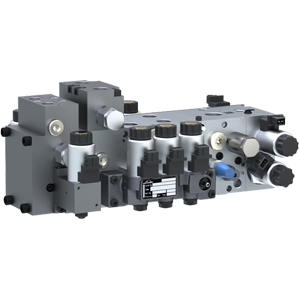

1x VW12M3 Load sensing directional control valvelsc monoblock

Learn More

1x VW12M3 Load sensing directional control valvelsc monoblock

Learn More

1x LINC 2, CED 13 For open and closed loop applicationslinde electronic control units of the linc series feature high mechanic and electric robustness

Learn More

1x LINC 2, CED 13 For open and closed loop applicationslinde electronic control units of the linc series feature high mechanic and electric robustness

Learn More

Linde Standard Product Portfolio

50 kW – 150 kW

Application Example

60 kW, 7.5 t, tractive effort 33 kN, ground speed 35 kph

Equipment

1x HPV 55-02 CA (Propel drive)

1x HMV 165-02 EH1P-CA PTO (Propel drive)

1x VW12M3 (Valve block)

1x Electronic control unit (For valves)

Advantages

- Reduced components and weight reduction (approximately 33%) thanks to the omission of the transfer box and manual gearbox

- More design space and better centre of gravity thanks to direct installation in the drivetrain

- No interruption of tractive effort

- Cost reduction in the drivetrain and radiator

Options

- Purely hydraulic or fully-electrified system

- Customer-specific assembly points, integrated brakes

- Tandem or double motor for larger machines or large conversion ratio designs

- Spread design with individual motors per axle

Teleloaders are versatile and their greater lift heights compared with tractors or wheeled loaders make them virtually indispensable at modern farms and construction sites. This example design depicts a telehandler with a partly electronified Linde drive system.

The working hydraulic system has an electrically controlled directional control valve block in layer brazing technology with optimised channel design. The propel drive unit is controlled hydro-mechanically and offers high tractive effort even at low engine speeds for smooth starting and precise manoeuvring. The telehander is smooth at all times, even when heavily loaded.

The pump controller is set to optimally utilise the available engine power in every situation. The displacement of the CA-type pump depends on engine speed. As a result, it can be operated intuitively. The diesel speed is captured hydrostatically - very robust, pressure compensated and virtually independent of the temperature.

However, its star feature is the custom PTO motor with through drive shaft, integrated mounting points and directly attached brake. It is fitted directly between the cardan shafts. No gearbox is required, allowing for rapid reversing. The driver is free at all times to give his full attention to the load being moved.

This configuration with a larger hydraulic motor enables the gearbox to be omitted, eliminating gear noise, enhancing overall efficiency and allowing a smaller radiator to be used. In addition to the reduced weight, this also helps to save fuel. The configuration is still approximately one third lighter than a model with a smaller motor and manual gearbox.

For particularly high tractive effort requirements, Linde PTO motors are also available as double or tandem motors which operate at large volumes. They have slender radial dimensions and higher top speeds than single motors of the same volume.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com