Crawler Crane

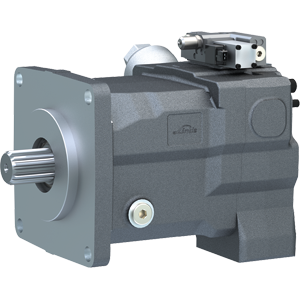

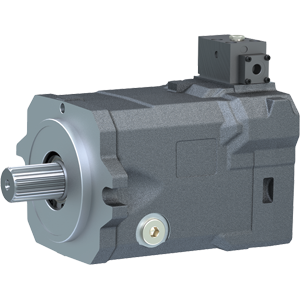

2x HPR 210 - 02Pump TandemFor open and closed loop operation

Learn More

2x HPR 210 - 02Pump TandemFor open and closed loop operation

Learn More

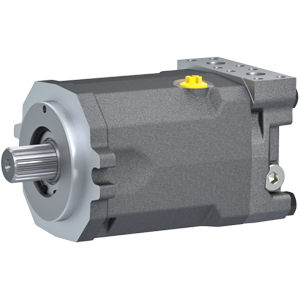

2x HMR 135 - 02 Displacement size from 55 to 210 ccself-regulating motors for open and closed circuits

Learn More

2x HMR 135 - 02 Displacement size from 55 to 210 ccself-regulating motors for open and closed circuits

Learn More

1x HMF 105 - 02 P Swing Drive Motorfixed displacement motors with integrated swing drive functions

Learn More

1x HMF 105 - 02 P Swing Drive Motorfixed displacement motors with integrated swing drive functions

Learn More

1x HMV 105 - 02 E2 Hoist Motor Variable displacement motors for closed and open loops

Learn More

1x HMV 105 - 02 E2 Hoist Motor Variable displacement motors for closed and open loops

Learn More

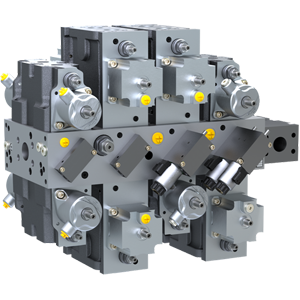

1x VT8 LSC VT MODULAR

Learn More

1x VT8 LSC VT MODULAR

Learn More

1x LINC 2, CEB 16/50 For open and closed loop applications Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

1x LINC 2, CEB 16/50 For open and closed loop applications Linde Electronic control units of the LINC series feature high mechanic and electric robustness

Learn More

Linde Standard Product Portfolio

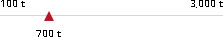

100 t - 3,000 t

Application Example

700 t

Equipment

2x HPR 210-02 (pump tandem)

2x HMR 135-02 (travel motors)

1x HMF 105-02 P (swing drive motor)

1x HMV 105-02 E2 (hoist motor)

1x VT8 (directional control valves)

1x LINC 2, CEB 16/50 (electronic control unit)

Advantages

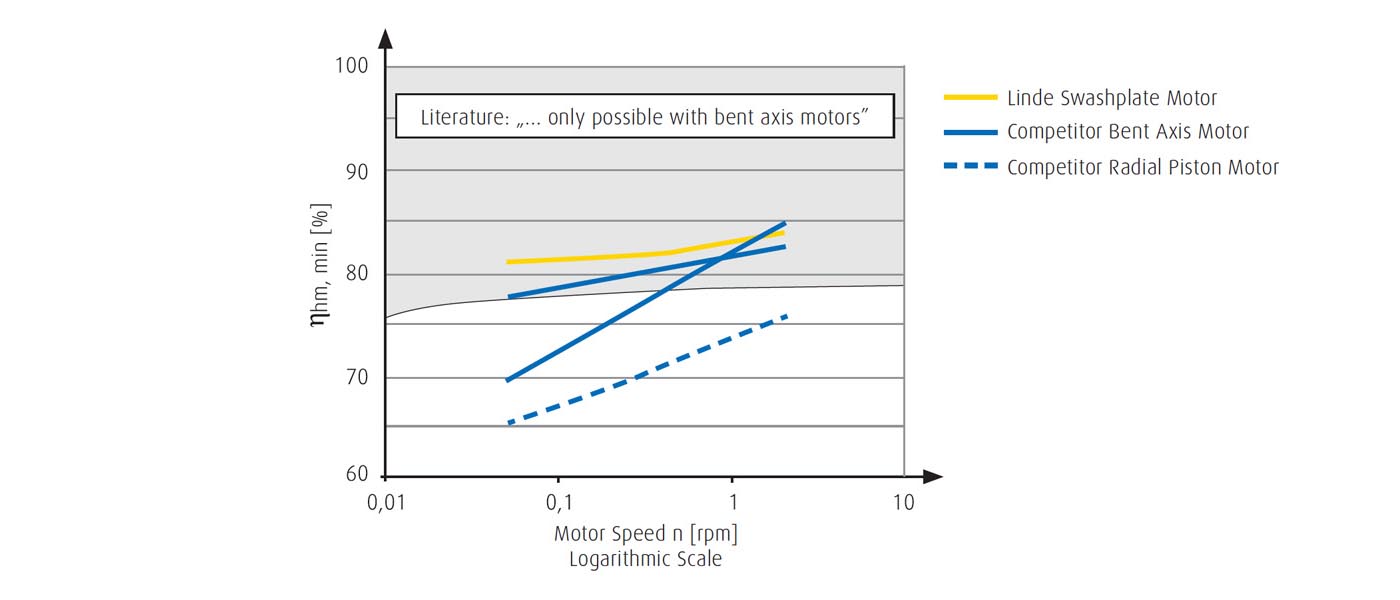

- excellent low speed and true running behaviour of the motors

- no jolting thanks to the control concept of the machine as a whole

- can be electrically controlled and retrofitted, even for individual sections

Options

- system scope and level of electrification can be scaled

- partial automation

The crawler crane utilises the full benefits of LSC technology: the combined movement of individual functions without mutual interactions or influences in all load situations ensures perfect positioning. Furthermore, the crane also benefits from jolt-free lifting and no lowering of loads at the start of the movement. The crane's design as a two-circuit system with two high-pressure self-regulating pumps for different pressure levels increases the demand-specific supply to the actuators, which makes the machine even more efficient. This ensures excellent load capacity in all working conditions. The superb low speed behaviour and the smooth, even running characteristic of the Linde motors is particularly noticeable when it comes to lifting and lowering the hook.

The individual valve sections in the control plates of the VT modular family can be actuated fully hydraulically or electro-hydraulically. The two types of control can also be combined in one control plate.

Thanks to the electronic controller, selected functions can also be operated by remote control or partially automated. Sophisticated safety systems are also possible, which can be implemented via locking mechanisms or through proportionally slower reactions from individual actuators in given situations.

Even without the use of position sensors, the machine can be equipped with the functions of the LSC+ system. In particular, this includes switching between rough control or fine control, or overriding the LS signal if load-dependent machine reactions are required. The maximum efficiency of single actuators is achieved, when they are controlled purely via the pump with fully open directional control valve pistons.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com