Forage Harvester

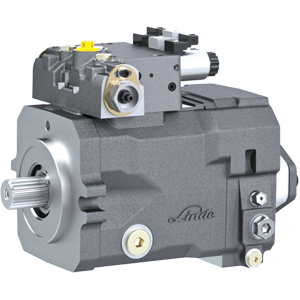

1x HPV 105-02 E2 Displacement size from 55 to 280 ccVariable pumps for closed circuit operation

Learn More

1x HPV 105-02 E2 Displacement size from 55 to 280 ccVariable pumps for closed circuit operation

Learn More

1x HMV 210-02 Displacement size from 55 to 280 cc Variable displacement motors for closed and open loops

Learn More

1x HMV 210-02 Displacement size from 55 to 280 cc Variable displacement motors for closed and open loops

Learn More

1x HMV 135-02 Displacement size from 55 to 280 cc Variable displacement motors for closed and open loops

Learn More

1x HMV 135-02 Displacement size from 55 to 280 cc Variable displacement motors for closed and open loops

Learn More

1x Electronic control unit For open and closed loop applications Linde electronic control units of the linc series feature high mechanic and electric robustness

Learn More

1x Electronic control unit For open and closed loop applications Linde electronic control units of the linc series feature high mechanic and electric robustness

Learn More

Linde Standard Product Portfolio

200 kW – 900 kW

Application Example

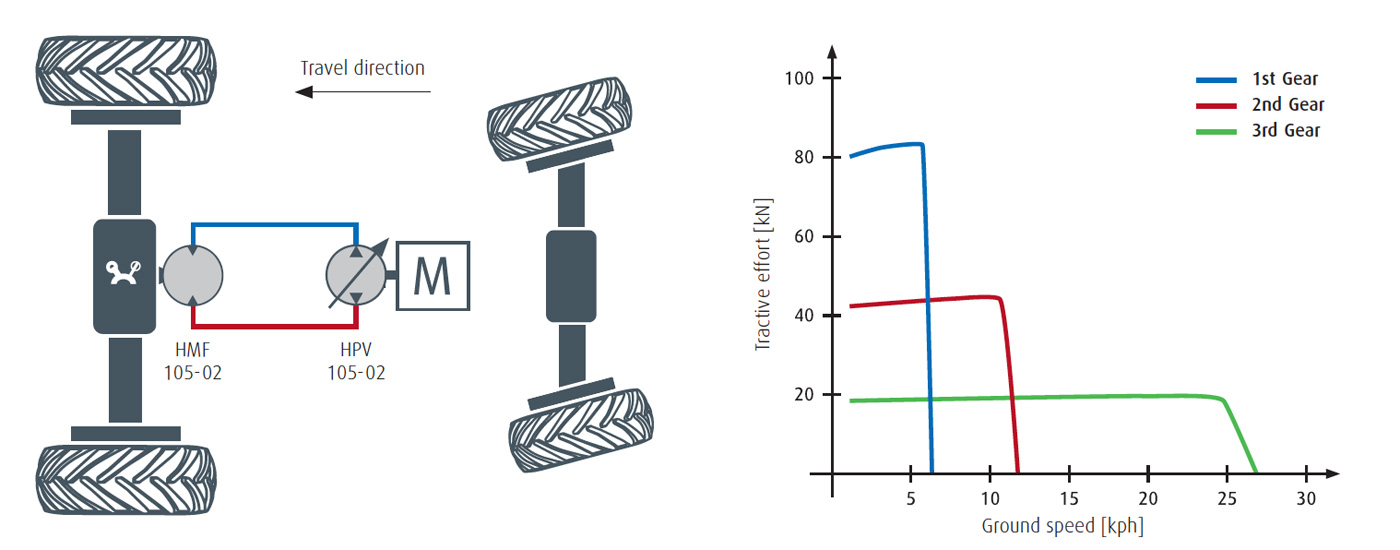

450 kW, 18 t, tractive effort 150 kN,

ground speed 40 kph

Equipment

1x HPV 105-02 E2 (Pump for propel drive)

1x HMV 210-02 (Motor at front axle)

1x HMV 135-02 (Motor at rear axle)

1x Electronic control unit

Advantages

- intelligent propel drive management thanks to electronic control

- high harvesting power and fuel efficiency

- safety and comfort features

- switchable intelligent hydraulic four-wheel drive

Options

- without or with permanent four wheel drive

- "Shift in Motion"

Harvesting performance up to 400 tonnes an hour, even when used 24 hours a day throughout the entire harvesting season. High performance and availability of a unit is independent of its type of control. Whether mechanically, hydraulically or electrically actuated, all Linde controls operate with absolute precision and reliability.

Intelligent electronic controls offer an extended range of sophisticated comfort-, application- and safety features. The controls ensure that the diesel engine, variable-displacement pump and -motor are perfectly matched to each other in every situation. Utilisation of the installed power is optimised, and the fuel is used efficiently. The electronics themselves offer an impressively high level of safety – in both concept and design. If, however, external circumstances cause the control signals to fail, the hydraulic units set their swash plate angles back to minimum volume. The machine decelerates moderately until standstill, without over-revving the diesel engine.

The powerful HMV 210-02 hydraulic motor enables speeds of up to 40 kph on the road. The harvesting gear covers a speed range up to 15 kph, which makes shifting gears unnecessary on the field. The optimum speed is pre-selected in each case, and is reliably maintained thanks to the automatic regulation; after turning round, it is rapidly regained.

A second hydraulic motor can be activated at the rear axle. The two units can be controlled independently of each other, and the axles are not mechanically coupled. The tractive effort is distributed to the front and rear axles to suit the situation so that the traction limit is reached on both axles simultaneously. The mechanical decoupling of the two axles protects the soil, even when driving in tight curves. Reducing the effective torque to zero ensures that the vehicle retains full steering properties at all times, even when decelerating sharply.

Proslav district, 3 Zhasmin Str.

4015 Plovdiv, Bulgaria

Tel.: +359 32 240033

Service manager: +359 885 899 692

Assistant: +359 885 899 691

Email: office@baggerhydraulik.com

Website: baggerhydraulik.com